Description

Product Description

Medium-density fibreboard (MDF)

Medium-density fibreboard (MDF) is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibres。 often in a defibrator, combining it with wax and a resin binder, and forming panels by applying high temperature and pressure. MDF is generally denser than plywood. It is made up of separated fibres, but can be used as a building material similar in application to plywood. It is stronger and much denser than particle board.

|

Product name

|

MDF

|

|

Advantage

|

Uniform material quality, dense lamellar structure, the surface flat and smooth, not easy to deformation, stable performance, the

edge light and smooth, not easy to collapse edge and layered, non-toxic, tasteless, non-radiation and good air permeability. Good thermal insulation performance, not aging and strong adhesion. |

|

Material

|

Polar, pine or hardwood

|

|

Specifications

|

Sizes: cut sizes , 1220*2440mm, 1830*2440mm, 1250*2465mm, or other customized sizes .

|

|

Thickness: 2-30mm

|

|

|

Technology parameters

|

Density: 500-920kg/m3

|

|

Moisture: 4-8%

|

|

|

Water absorption rate: ≤10%

|

|

|

Modulus of elasticity: >3700Mpa

|

|

|

Tolerance: length/width: +/-2mm

|

|

|

Tolerance: Thickness: +/-0.2mm

|

|

|

Formaldehyde Release

|

E0, E1, E2

|

|

Certificate

|

ISO9001, CARB, FSC

|

|

Delivery Time

|

Within 3weeks |

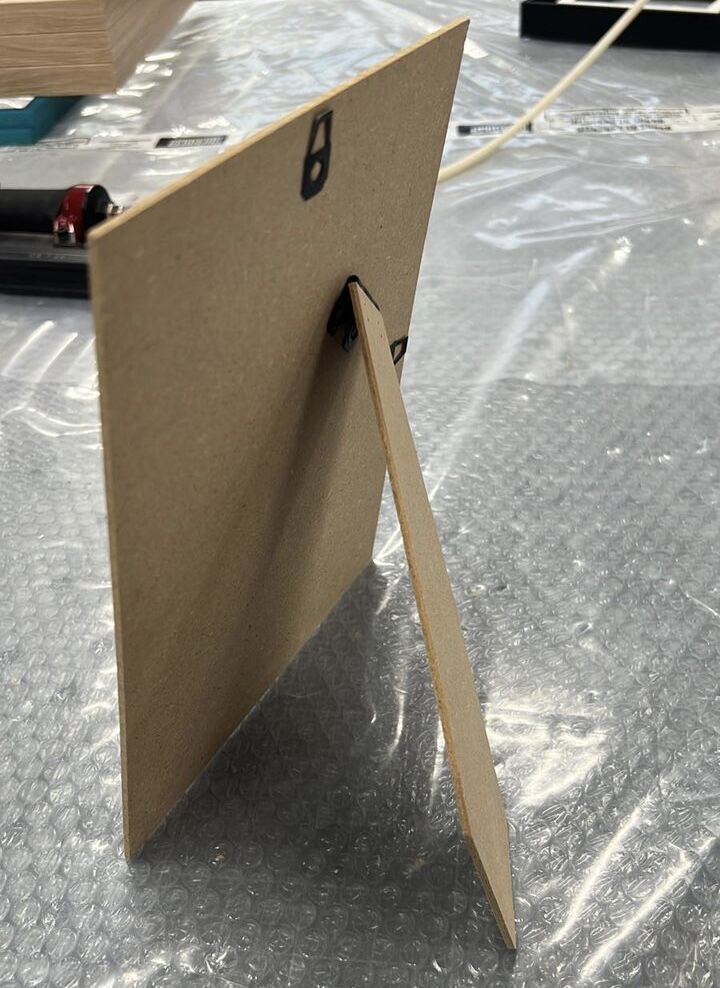

| Style | Clean board /with leg and hanger |

|

Package

|

Inner packing: Inside pallet is wrapped with a 0.2mm plastic bag

|

|

Outer packing: Pallets are covered with fiber board /cardboard and then steel tape for strength

|

|

|

Usage

|

furniture (door, bed. etc), laminate flooring, decorative materials, packing, etc.

|

Reviews

There are no reviews yet.