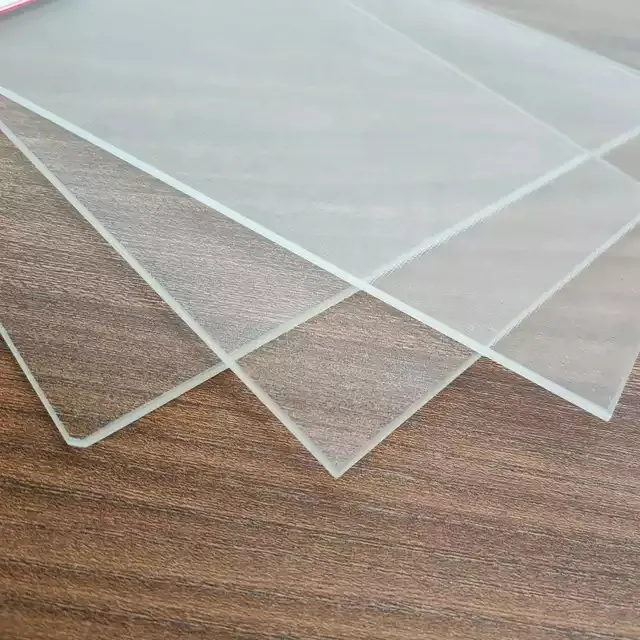

AR high-transmission anti-reflection glass (Anti-reflection glass) is also called anti-reflection glass or anti-reflection glass.

It is a kind of glass whose surface is specially treated. The principle is to process high-quality glass on one or both sides.

AR high transmission and anti-reflection glass has high transmittance and low reflectivity. The transmittance can reach 99% at a certain peak, and the reflectance is less than 1%. Compared with ordinary glass, AR high-transparency anti-reflection glass has a lower reflectance, which reduces the reflectance of light to below 1%. In the visible light range, its one-sided reflectance is about 4%.

The total spectral reflectance is about 8%. The anti-reflection effect of the glass surface in the visible light range can be achieved by two methods; one is to use different optical materials The interference effect produced by the film layer eliminates the incident light and reflected light, thereby increasing the transmittance.

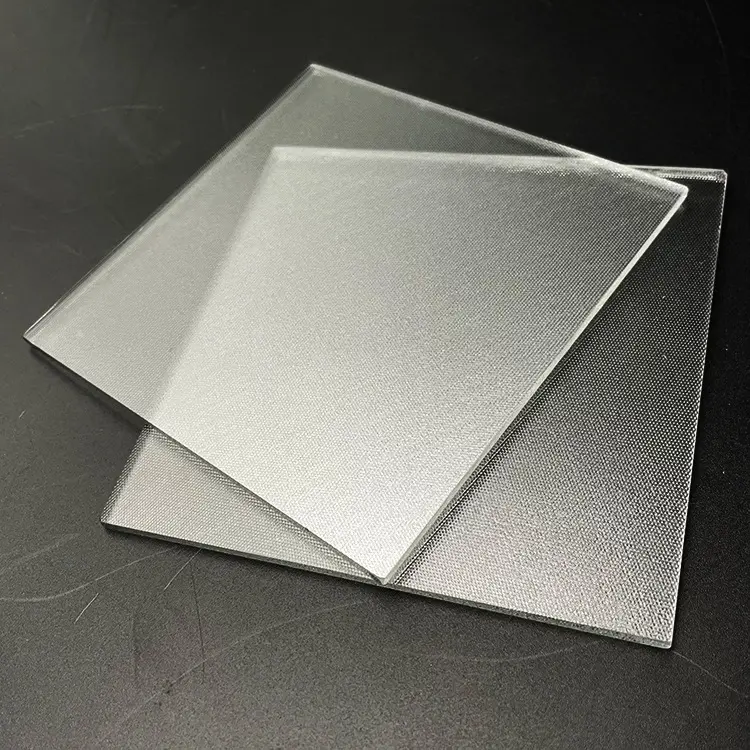

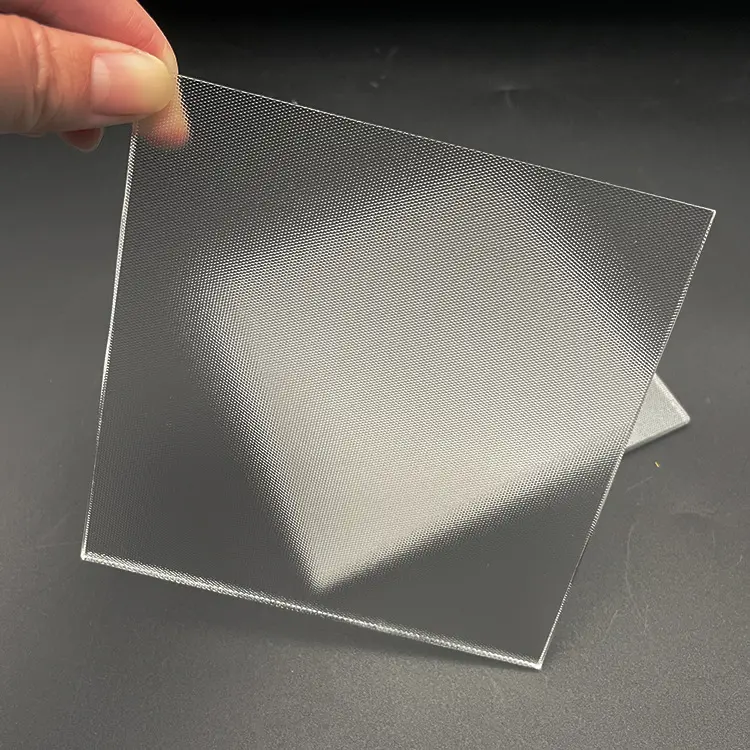

This kind of glass produced by the destructive interference of light is called AR glass; another method is to use the scattering effect of the rough surface Converting a large amount of incident light into diffuse reflection light will not bring significant changes to the transmittance. This kind of glass produced by fine roughening is called AG glass.

Advantages of AR glass

1. The highest peak visible light transmittance is 99%, and the average visible light transmittance exceeds 95%, greatly improving LCD,

The original brightness of PDP reduces energy consumption.

2. The average reflectance is less than 4%, and the lowest value is less than 0.5%, which effectively weakens the image distortion caused by the strong light behind.

No regrets, enjoy clearer image quality.

3. The color is brighter and the contrast is stronger, which makes the image color contrast stronger and the scenery clearer.

4. Anti-ultraviolet rays, effectively protect the eyes The transmittance in the ultraviolet spectrum region is greatly reduced, which can effectively prevent the damage of ultraviolet rays to the eyes.

5. High temperature resistant AR glass temperature resistance > 500 degrees (general acrylic can only withstand temperature 80 degrees)

6. Excellent scratch resistance and wear resistance

The hardness of the AR glass film layer is equivalent to that of glass, greater than 7H, (the hardness of the general PC board is about 2H to 3H).

7. It can be cleaned by various cleaning agents, and can be wiped by acid and alkali cleaning agents, and the film layer will not be damaged.

8. Strong impact resistance The impact performance of 3mm thick glass is equivalent to 6mm acrylic.

9. Keep the angle of view Generally, after the acrylic is installed, the angle of view will become smaller; but after the AR glass is installed, the angle of view will not become smaller.

10. Appearance

The surface flatness of AR glass is much better than that of coated acrylic, and the larger the size, the more obvious the difference.

11. The cold and heat deformation of AR glass is almost negligible, and it is suitable for all kinds of environments; at the same time, AR glass has a glazed feel and a more beautiful appearance

Main Application

Ordinary LCD monitors and LCD TVs do not have a front glass in front of them. The surface is easily damaged by scratches, and the viewing angle is small. After adding a kind of AR glass, these shortcomings will be overcome. Mainly used for protective screens of display devices such as LCD TVs, PDP TVs, laptop computers, desktop computer displays, high-end instrument panels, touch screens, photo frame glass and other electronic products that increase transmittance and reduce reflectivity.

1. Basic concepts:

Anti-reflection glass (AR) is also called anti-reflection glass. AR glass adopts the principle of optical thin film interference, and through the vacuum magnetron reactive sputtering advanced technology, a nano-optical multilayer film with a certain film structure is plated on the glass substrate, which increases the visible light transmittance of the glass from 89% to more than 98%. , the surface reflected light is reduced from 8% to less than 1%, high transparency and no reflection under strong external light, anti-glare, greatly improving the contrast and clarity of the flat panel display in a strong light environment, and at the same time partially improving the brightness of the display, with high Eye-clearing function

2. Product application:

Mainly used for protective screens of display devices such as LCD TVs, PDP TVs, laptop computers, desktop computers, outdoor display screens, medical instruments, cameras, display kitchen window glass, military display panels and other functional glass

3. Film structure:

A. Single-sided AR (double layer) GLASS\TIO2\SIO2

B. Double-sided AR (four layers) SIO2\TIO2\GLASS\TIO2\SIO2

C. Multi-layer AR (can be customized according to customer requirements)

4. The transmittance is increased from about 88% of ordinary glass to more than 95% (up to 99.5%, which is also related to the thickness and material selection).

5. The reflectivity is reduced from 8% of ordinary glass to less than 2% (up to 0.2%), effectively weakening the defect of whitening the picture caused by strong light behind, and enjoying a clearer image quality

6. Reduce the UV spectrum transmittance

7. Excellent scratch resistance, hardness >= 7H

8. Excellent environmental resistance, after acid resistance, alkali resistance, solvent resistance, temperature cycle, high temperature and other tests, the film layer has no obvious change

High transmission and anti-reflection glass is also called AR glass, which is divided into single-sided AR glass and double-sided AR glass

Community Interactive Screen AR Glass High Transmittance Anti-reflection Glass Double Coated Low Reflection AR Glass

Features of tempered glass:

1. Tempered glass is a glass deep-processed product obtained by heating the glass to a temperature close to the softening point of the glass (600-650°C) for rapid cooling or chemical tempering. It has good mechanical properties and thermal shock resistance, also known as strengthened glass.

2. The treated surface of the glass produces uniform compressive stress, its strength is 3-10 times that of the glass that has been well annealed, and its impact resistance is also greatly improved. When tempered glass is broken, there will be network cracks or fine particles, which will not hurt people, so it is also called safety glass.

3. The thermal shock resistance of tempered glass is very good, the highest safe working temperature is 287.78 ℃, and can withstand the temperature difference of 204.44 ℃. Therefore, it can be used to manufacture observation windows on high-temperature furnace doors, radiant gas heaters and dryers, etc.

4. Due to the good performance of tempered glass, it has been widely used in the automobile industry, construction engineering and fields. It is often used as doors, windows, curtain walls, shielding and shop windows of high-rise buildings, portholes of warships and ships, and desktop glass. Tempered glass is now used in many electronic and electrical products.

5. Mainly dedicated to the field of electronic and electrical glass, providing glass products for many instruments and electronic displays.

The role of safety glass:

1. Safety: If the glass is broken, the fragments will be like honeycomb-shaped broken small obtuse particles, which will not cause human harm.

2. High strength: For tempered glass of the same thickness, the impact strength is 3 to 6 times that of ordinary glass, and the bending strength is also 3 to 6 times that of ordinary glass.

3. Thermal stability: Tempered glass has strong thermal stability, and the temperature difference it can withstand is three times that of ordinary glass, and it can withstand temperature changes of 200 °C.

4. Improved safety: After tempered glass is damaged by force, it will quickly present tiny obtuse-angle particles, thereby ensuring personal safety to the maximum extent.

Ultra-white glass

Ultra-white glass has fewer impurities, lower iron content, is more transparent, and looks whiter. Ordinary glass is somewhat green due to iron impurities. Ordinary glass and ultra-clear glass can also be distinguished from the front. After all, the transparency of ultra-clear glass is much higher, and the thicker it is, the more obvious it is.

Compared with ordinary glass, ultra-clear glass will be much more expensive, because its cost is even more expensive, and it has not yet been popularized in China.

Ultra-white glass, also known as colorless glass, high-transparency glass, and low-iron glass, is the top-grade variety of glass products. It has high light transmittance and high transparency. The product is crystal clear, noble and elegant, and has a glass family “Crystal Prince”. known as. The light transmittance determines the quality of glass. The light transmittance of float glass is 86%, while the light transmittance of ultra-clear glass can reach more than 92%.

Silk screen glass In modern society, people need to use a lot of glass products in their daily life, and it is impossible to get rid of glass. Glass is stable, resistant to strong acids and alkalis, hard and durable, and is one of the raw materials required for most important equipment. Ms. Ming Hexiang Glass will take you to further understand the relevant information of glass screen printing, understand the materials required and the selection method of materials, read this article to learn more.

1. Ink: ink is necessary for silk screen printing, there is no pattern where the ink comes from. There are many colors of ink, and the master of screen printing must learn to adjust the ink.

2. Stencil: The stencil is prepared for printing patterns on the glass. First apply photosensitive glue on the screen, and then combine film and strong light to make the pattern on the screen. Put the film under the screen, then expose the photosensitive adhesive on the screen with strong light, and then rinse off the photosensitive adhesive on the part blocked by the film, and the pattern is made.

3. Oven: The oven reminds us of baking. Yes, it is to put the glass in the oven to bake. After the glass is printed with a pattern, the ink on it is not dried quickly. If you take the glass at this time, you will touch it. ink, which will destroy the pattern. After passing through the oven, the ink will dry and the pattern will not be easily erased.

4. Tempering furnace: Why do we need to go through the tempering furnace? Silk screen printing is divided into high temperature screen printing ink and low temperature screen printing ink. High temperature screen printing ink must be screen printed first and then pass through the tempering furnace. This way the ink fuses with the glass surface, making it impossible for you to wipe off the ink.

Community Interactive Screen AR Glass High Transmittance Anti-reflection Glass Double Coated Low Reflection AR Glass