1 What is high borosilicate fireproof glass?

The basic components of high borosilicate fireproof glass are silicon dioxide, boron trioxide, and sodium oxide.

It is the preferred material for single-piece fireproof glass. It can also be made into building energy-saving fireproof materials with better comprehensive performance by coating and hollowing processes. The size of the original film can reach up to 4500mm×2440mm, the thickness is 4mm~15mm, and the intermediate size can be produced according to customer needs.

Excellent performance:

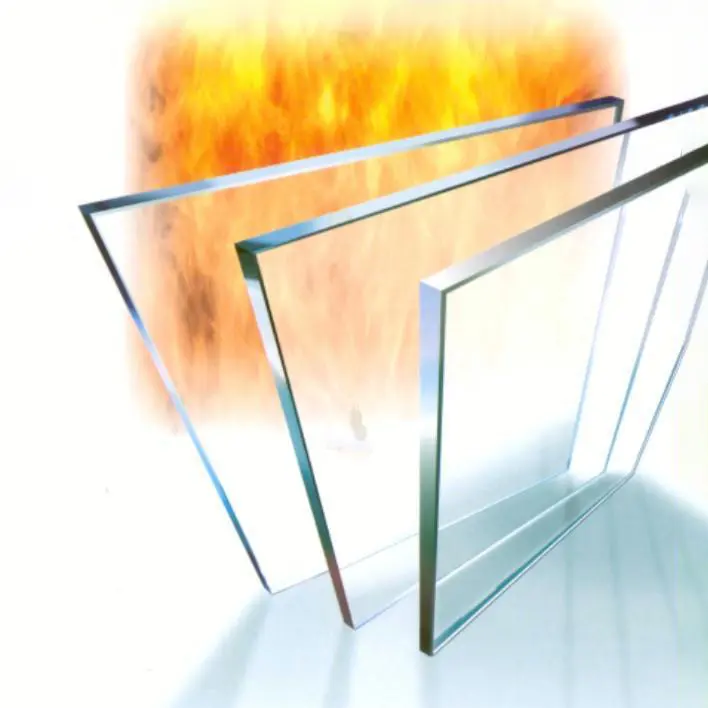

☑ Excellent fire resistance

Ultra-high softening point, stable and fundamental guarantee for fire performance, fire resistance time over 120 minutes. With ultra-high transparency, while maintaining the transparency and beauty of the building, it can still ensure people’s vision in case of fire to facilitate escape and rescue.

☑ High-strength and ultra-light performance

The weight is more than 8% lighter than ordinary glass, and at the same time it has super high mechanical strength, which is extremely strong and light, which can significantly reduce the weight of buildings.

☑ Excellent optical performance

Low iron, environmentally friendly formula, high light transmittance, visible light transmittance 92%, excellent optical quality provides distortion-free visual effects.

☑ High chemical stability

Acid resistance, alkali resistance, UV resistance, good fire resistance.

☑ No risk of self-explosion

Self-explosion is a major hidden danger that is extremely difficult to overcome in building safety glass at present. Because high borosilicate fire-resistant glass does not contain nickel in its raw materials and systems, there is no nickel sulfide crystal in all glass products, which eliminates the hidden danger of self-explosion.

☑Machinability

Before tempering, high borosilicate glass can be processed by cutting, edging, drilling, coating and so on. High borosilicate glass can be used together with other glass to make building energy-saving and fireproof materials with better comprehensive performance by laminating, hollowing, vacuum and other processes.

☑ Double security guarantee

Fully tempered monolithic high borosilicate fireproof glass, meeting fireproof and safety performance requirements.

2 Application of high borosilicate fireproof glass

During a fire, the failure of glass will change the ventilation of the building, thereby affecting the fire.

The reasons for glass damage mainly include external impact, uneven heating, cracking, and thermal melting deformation.

Ordinary single-piece fire-resistant glass will burst when exposed to water at a high temperature of about 400 ° C ~ 500 ° C. Composite heat-insulating fire-resistant glass will burst but will not penetrate. , Ordinary high borosilicate fireproof glass can not burst when it meets water when it reaches 800 ℃.

Application of high borosilicate 4.0 glass:

glass curtain wall (upper left), fire partition (upper right), smoke barrier (lower left), fireproof window (lower right)

The tempered high borosilicate fireproof glass is mainly used in fireproof windows, indoor fireproof partitions, and fireproof doors.

It can be used as a curtain wall alone, and can also be processed by coating, lamination, hollowing, and colored glaze.

At the same time, because it can resist high temperature and will not break when exposed to water, it can also be developed in the direction of craft glass and applied to the panels of microwave ovens and induction cookers.

Application of high borosilicate 3.3 glass:

electric oven baffle (upper left), cinema projector lens (upper right), induction cooker panel (lower left), baffle of disinfection cabinet (lower right)