Maybe many people have a one-sided understanding of glass types, only know some ordinary glass and tempered glass, etc.

However, as home appliances are becoming more and more exquisite nowadays, many home appliances need to have a certain degree of vitrification, so that they can be greatly increased.

The appearance of home appliances brings a very good experience to consumers.

This requires everyone to understand the silk screen glass of home appliances.

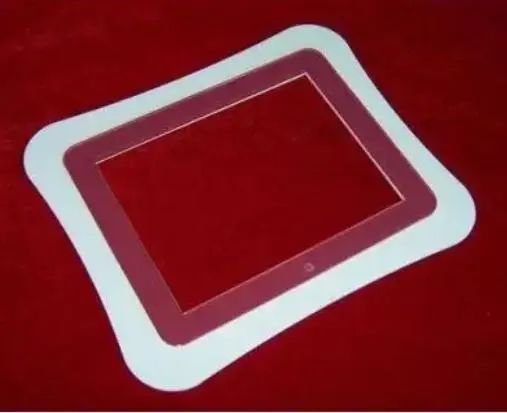

This kind of glass is more beautiful than ordinary glass, and can be made into many different forms and structures. It can be seen in various scenes in life. This requires everyone to understand Familiar with the basic content and technical characteristics of screen printing glass for home appliances.

Main materials and tools for home appliance screen printing glass

For those experienced glass manufacturers, the following materials and tools need to be prepared to make home appliance silk screen glass, which are flat glass, photosensitive glue, film, special ink for silk screen, etc., so that home appliance screen printing glass can be done. make.

At the same time, in the production process, in order to greatly simplify the production process, we also need to use some useful tools, such as strong lights, tempering furnaces, ovens, mesh panels, etc., which can often achieve twice the result with half the effort.

Home appliance screen printing glass processing form

Since this home appliance screen printing glass has been widely used in our lives, it can be applied to a variety of different home appliances, thereby greatly increasing the visual effect of home appliances and being favored by more consumers.

Therefore, screen printing glass for home appliances has also developed rapidly to a certain extent. It is mainly divided into two different processing forms, namely manual screen printing and machine screen printing. The operation methods are slightly different. You can make corresponding choices according to your actual situation.

Home appliance screen printing glass molding conditions

Home appliance screen printing glass will have a variety of patterns, and these pictures are drawn by ink, and the ink is also divided into many different colors and types, which can be prepared by experienced technicians, so it can be made Home appliance silk screen glass has some really nice patterns. Therefore, the requirements for these technicians are relatively high, not only need to have a certain ability to mix ink, but also need to have a certain ability to paint.

In the specific production process, it is necessary to apply a layer of photosensitive glue on the screen printing glass plate of home appliances, and then add film, under the double function, the pattern can be formed on the screen, and under the continuous irradiation of strong light , the photosensitive glue can be quickly solidified.

Next, you only need to wash off the photosensitive glue blocked by the film, and the rest is the pattern you made. If you want to get a more refined pattern content, you can also perform more detailed steps. , so as to complete the production of home appliance screen printing glass.

In the specific production process, it is necessary to apply a layer of photosensitive glue on the screen printing glass plate of home appliances, and then add film, under the double function, the pattern can be formed on the screen, and under the continuous irradiation of strong light , the photosensitive glue can be quickly solidified.

Next, you only need to wash off the photosensitive glue blocked by the film, and the rest is the pattern you made. If you want to get a more refined pattern content, you can also perform more detailed steps. , so as to complete the production of home appliance screen printing glass.