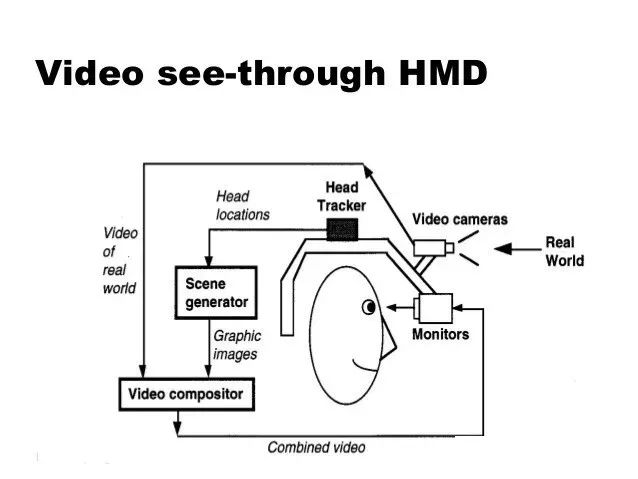

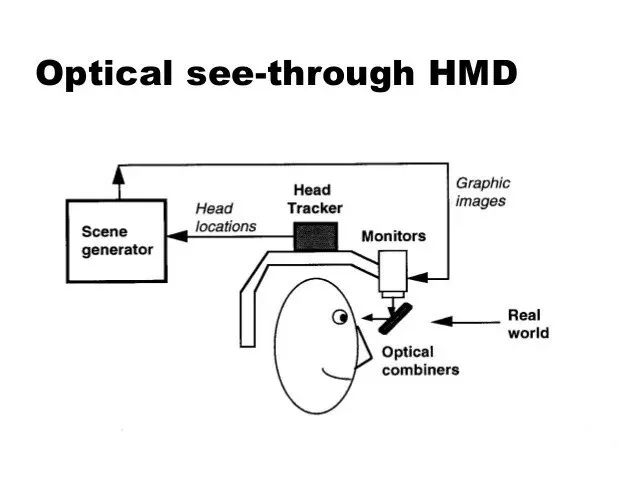

There are two main types of AR core technologies today, namely Video see-through and Optical see-through.

The advantage of the video perspective solution (above) lies in its field of view (FOV), and based on the preprocessing of the video.

The superimposed AR information effect is more outstanding, but the disadvantage is that the image collected by the camera is processed And after reaching human vision, there is usually a significant delay…

The advantage of optical see-through (pictured above) is that AR information is directly superimposed on the real vision of the human eye through transparent lenses, so there is no delay problem. However, the limitation of the optical see-through solution lies in the current stage. AR information display and superimposition effects require additional computer vision and corresponding preprocessing solutions, but correspondingly increase the power consumption and weight of wearable AR products.

However, the founder of Lingxi, a leading domestic AR solution provider, mentioned in a forum that he believes that optical see-through solutions will be the mainstream of wearable AR. The main reason is that as computer vision chips and higher-integration AI chips can be more effectively integrated into wearable AR devices for optical see-through solutions, and AR optical modules continue to evolve towards lightweight, they can solve optical see-through solutions. The disadvantage of being relatively heavy and benefiting from high integration, it can save more power and improve battery life.

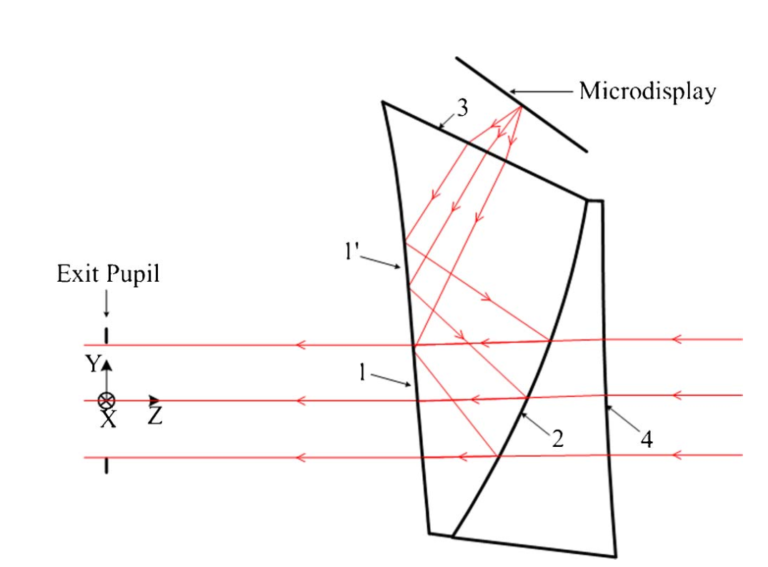

Our common optical instruments are often rotationally symmetrical optical structures, such as microscopes and telescopes, and you will see images no matter what angle you look at them from. The rotationally symmetric structure has continued to this day because of its ease of design and production, but for AR glasses, the device we expect is just like the glasses we usually wear, just need to be fixed on the head, and we don’t need to rotate the lens. So can we give up the rotational symmetry of the optical structure to obtain better performance? This requires the use of free-form surface technology.

Free-form surface refers to a surface whose surface shape cannot be continuously processed and has the arbitrary characteristics of traditional processing. Freeform surface is an optical design method that obtains better performance by giving up rotational symmetry. The optical structure diagram of a common AR free-form surface display device is as follows:

On the top is a microdisplay, such as oled, microled, etc. The light from the microdisplay will enter the optical glass in the middle, and a total reflection will occur first, and then a reflection will occur on the semi-transparent and semi-reflective film in the middle, and the light from the outside will Projected directly in, the final combination forms a virtual fusion image.

As for the pursuit of a visual feast, as a small glass, it has never stopped exploring and innovating. As one of the optical glasses, AR glass is such a kind of glass. Even if the glass is placed in front of you, no matter whether it is placed flat, vertically or tilted, the shadow of any object will not be reflected on the glass surface. Objects can be clearly presented in front of everyone through the glass. Under strong light, the reflectivity of the glass is so low that it is not even noticeable.

AR high-transmission anti-reflection glass (Anti-reflection glass) is also called anti-reflection glass or anti-reflection glass. It is a kind of glass whose surface is specially treated. The principle is to process high-quality glass on one or both sides.

AR high transmission and anti-reflection glass has high transmittance and low reflectivity. The transmittance can reach 99% at a certain peak, and the reflectance is <1%. Compared with ordinary glass, AR high-transparency anti-reflection glass has a lower reflectance, which reduces the reflectance of light to less than 1%. Ordinary glass has a one-sided reflectance of about 4% in the visible light range. The total spectral reflectance is about 8%. The anti-reflection effect of the glass surface in the visible light range can be achieved by two methods; one is to use the interference effect produced by different optical material film layers to eliminate incident light and reflected light, thereby improving the transmittance method, this method uses The glass produced by the destructive interference of light is called AR glass; another method is to use the scattering effect of the rough surface to convert a large amount of incident light into diffuse reflection light, which will not bring significant changes to the transmittance, which is A glass produced by fine roughening is called AG glass.

Film structure

A. Single-sided AR (double layer) GLASS\TIO2\SIO2

B. Double-sided AR (four layers) SIO2\TIO2\GLASS\TIO2\SIO2

C. Multi-layer AR (can be customized according to customer requirements)

Advantages of AR glass

1. High peak visible light transmittance of 99% The average visible light transmittance exceeds 95%, which greatly improves the original brightness of LCD and PDP and reduces energy consumption.

2. The average reflectance is less than 4%, and the minimum value is less than 0.5%, which can effectively reduce the defect of whitening the picture caused by the strong light behind, and enjoy a clearer image quality.

3. The color is brighter and the contrast is stronger, which makes the image color contrast stronger and the scenery clearer.

4. Anti-ultraviolet rays, effectively protect the eyes The transmittance in the ultraviolet spectrum region is greatly reduced, which can effectively prevent the damage of ultraviolet rays to the eyes.

5. High temperature resistant AR glass temperature resistance > 500 degrees (general acrylic can only withstand temperature 80 degrees)

6. Good scratch resistance and wear resistance

The hardness of the AR glass film layer is equivalent to that of glass, greater than 7H, (the hardness of the general PC board is about 2H to 3H).

7. It can be cleaned by various cleaning agents, and can be wiped by acid and alkali cleaning agents, and the film layer will not be damaged.

8. Strong impact resistance The impact performance of 3mm thick glass is equivalent to 6mm acrylic.

9. Keep the angle of view Generally, after the acrylic is installed, the angle of view will become smaller; but after the AR glass is installed, the angle of view will not become smaller.

10. Appearance: The surface flatness of AR glass is much better than that of coated acrylic, and the larger the size, the more obvious the difference.

11. The cold and heat deformation of AR glass is almost negligible, and it is suitable for various environments; at the same time, AR glass has a glazed feel and a more beautiful appearance.

Main application

There is no front glass in front of the general LCD monitor and LCD TV.

The surface is easily damaged by scratches, and the viewing angle is small. After adding a kind of AR glass, these shortcomings will be overcome. Mainly used for protective screens of display devices such as LCD TVs, PDP TVs, laptop computers, desktop computer displays, high-end instrument panels, touch screens, photo frame glass and other electronic products that increase transmittance and reduce reflectivity.