Glass is an indispensable material component of modern architecture. Glass is used in different building parts. Especially on the exterior windows, because of the transparent lighting and thermal insulation of the glass, it has become the most important building envelope component. In different occasions, glass with different functions is also required.

Various functional kilometers such as toughened glass, insulating glass, and heat-reflecting glass have emerged as the times require, representing the current technological level of the glass industry. Let’s revisit these glass products with unique technology today

1. Tempered glass

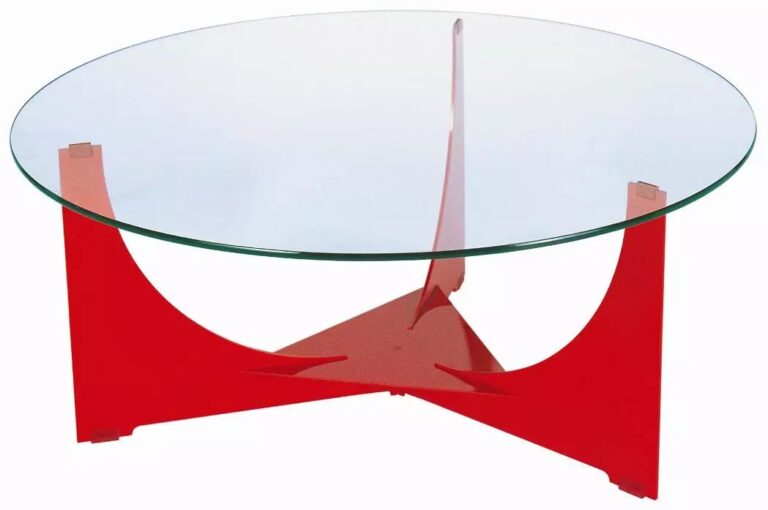

Tempered glass is made by heating the float glass to near the softening point in the tempering furnace, and then cooling it quickly and uniformly to form a uniform compressive stress on its surface, so as to improve its mechanical strength and effectively improve the wind pressure and impact resistance of the glass. Performance, improve glass thermal shock resistance.

Tempered glass is widely used in places that require relatively high mechanical strength and safety. Such as glass doors and windows, building curtain walls, glass furniture, indoor partitions, elevators, furniture, etc.

Performance characteristics of tempered glass

1) Safety: When broken, it splits into small obtuse particles similar to honeycomb, which hardly causes major harm to the human body. Ordinary glass breaks into sharp and large flakes, which can easily cause serious injury to the human body.

2) High strength: 4-5 times stronger than ordinary glass of the same thickness.

3) Stable heat resistance: It has good thermal stability, and the temperature it can withstand is about three times that of ordinary glass of the same thickness, and it can withstand a temperature change of 200°C. Therefore, it can play a short-term fire prevention role in the event of a fire.

4) Large disturbance: 3-4 times larger than ordinary glass of the same thickness. When tempered glass is loaded, its maximum tensile stress is not located on the surface of the glass like ordinary glass, but in the center of the tempered glass plate.

Self-explosion phenomenon of tempered glass

Self-explosion refers to the phenomenon that tempered glass bursts automatically without direct external force. The self-explosion phenomenon is mainly caused by the volume expansion caused by the phase transition of nickel sulfide (NIS) in the glass. Since nickel sulfide is mainly brought in from impurities in glass raw materials, it is still impossible to prevent the self-explosion of tempered glass.

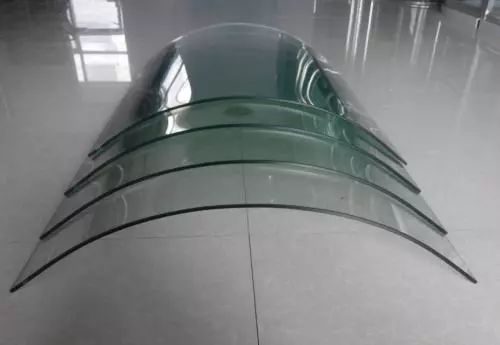

Hot bent tempered glass

Hot-bending tempered glass is to heat the original float glass to the softening temperature, then bend it by its own weight or external force, and cool it naturally to make the required curved glass. Hot-bending tempered glass is made after the glass is bent and shaped, and then quickly air-cooled by special equipment.

Hot-bending tempered glass is mostly used in curved glass curtain walls, lighting sheds, sightseeing elevators, indoor curved glass partitions, glass guardrails, interior decoration, furniture, etc.

Features of hot-bent tempered glass

The safety, impact resistance, and thermal stability are the same as flat tempered glass, and its wind resistance and disturbance performance are higher than semi-tempered glass. It is safety glass.

Laminated Glass

Laminated glass is a composite glass made by sandwiching tough polyvinyl butyral film (PVB) between two pieces of glass or multiple pieces of glass after high temperature and high pressure.

Due to the very good toughness of the PVB film, when the laminated glass is broken by an external force, the film layer will absorb a large amount of impact and make it decay rapidly, because the laminated glass is difficult to be broken down. Even if the laminated glass is broken, the glass fragments are basically Adhesive on the film, keep the fragments on the whole piece of laminated glass from falling off, so it becomes a real safety glass.

Laminated glass made of transparent PVB film has basically the same appearance and installation method as ordinary glass, and is durable. Widely used in building skylights, canopies, high-end curtain walls, doors and windows, showcases, furniture, elevators, etc.

Performance characteristics of laminated glass

1) Safety: The laminated glass installed on the building is subject to any external impact, even if the glass is broken, it can still be kept intact in the original frame, and has a certain effect of shielding from wind and rain.

2) Noise-reducing PVB film has a blocking effect on sound waves, thereby reducing noise and reducing noise interference at work or at home.

3) Anti-ultraviolet: It has a great blocking effect on ultraviolet rays in sunlight (up to more than 99%), and avoids ultraviolet radiation. Therefore, it can protect valuable indoor furniture or artwork from fading due to ultraviolet rays.

4) Bullet-proof and explosion-proof: multiple levels of bullet-proof and explosion-proof glass can be manufactured by using multi-layer laminated glass.

5) Security: Because it is impossible to effectively cut the installed laminated glass with a glass knife, and it takes a long time to penetrate the laminated glass with other tools and the sound is loud, it is difficult to enter the room by cutting or breaking the laminated glass and it is easy to be found. Strong resistance to vandalism, theft and violence.

6) Anti-hurricane and earthquake: Due to the high toughness and strong adhesion of laminated glass, even if the laminated glass is broken, the fragments still remain in place, and it is more suitable for use in hurricane and earthquake areas.

Insulating Glass

Insulating glass is a glass product made of two or more pieces of glass separated by a certain width of space with an aluminum frame filled with molecular sieve adsorbent, bonded and sealed with butyl glue, and then sealed with silicone glue or structural glue. It has good sound insulation, heat insulation, heat preservation, anti-condensation and other effects.

Insulating glass is widely used in various types of building curtain wall doors and windows, indoor partitions or freezers, etc.

Spacer frame thickness of insulating glass

6mm(6A), 9mm(9A), 12mm(12A), 15mm(15A) 18mm(18A)

21mm(21A) 24mm(24A) 27mm(27A)

The performance and characteristics of insulating glass

1) Sound insulation performance: Insulating glass is an ideal noise insulation material, which can generally reduce noise by 30 decibels, and filling it with inert gas can reduce it by about 5 decibels on the original basis.

2) Heat insulation performance: It can effectively reduce the U value of the heat transfer coefficient. If filled with inert gas, the heat transfer coefficient can be further reduced.

3) Anti-condensation performance: Since enough desiccant is filled in the spacer of the insulating glass, it can effectively absorb the water vapor that may infiltrate the inner cavity and the outside world, and ensure that the air in the inner cavity of the insulating glass is absolutely dry, so it has good performance. anti-condensation performance.

4) Its optical properties: thermal conductivity and thermal insulation coefficient are in line with national standards.

Low-emissivity coated glass

Low-emissivity coated glass, also known as LOW-E glass, is a film system product composed of multi-layer metal compounds coated on the surface of float glass by using magnetron true sputtering equipment.

The heat is reflected back to the room and reduces the conduction of the glass itself, thereby greatly reducing heat loss. In summer, it can reduce the radiation of outdoor heat to the room and play a good role in heat insulation.

Therefore, its film layer can block the heat transfer caused by indoor infrared radiation, has a high reflectivity for mid- and far-infrared rays, and has excellent heat insulation performance. In addition, its variety of color choices meets the requirements of strong decoration of buildings.

Features of LOW-E glass

1) It has high visible light transmittance, ground reflectivity, low emissivity, wide range of lighting, and soft light quality, which can avoid light pollution and create a good ecological environment.

2) Effectively control solar radiation, block mid-to-far infrared radiation, lower heat transfer coefficient U value, enhance heat insulation performance, and have good heat preservation and energy saving effects.

3) Effectively block the penetration of ultraviolet rays. Prevents fading of indoor furniture, fabrics, artwork.

Fire-proof glass

The ordinary glass is specially treated by physical and chemical methods to improve the thermal shock resistance of the glass, which can ensure that it will not break under flame impact and high temperature within 45-90 minutes, so as to prevent the flame from passing through the glass and spreading the fire.

Make people have enough time to evacuate the scene, fire fighting and disaster relief.

Performance and characteristics of fireproof glass

Fire-resistant glass is divided into three categories according to the fire-resistant performance level

Class A)

Fire-resistant glass that meets the fire-resistant and heat-insulating requirements at the same time. Including composite fireproof glass and perfusion fireproof glass. This kind of glass has the properties of light transmission, fire prevention (smoke, fire, and heat radiation), sound insulation, and impact resistance. It is suitable for architectural decoration steel and wood fire doors, windows, lighting, blocking walls, lighting roofs, and smoke blocking. In hanging walls, see-through floors, and other building components that need to be both transparent and fire resistant.

Class B)

Fire-resistant glass for ships, including fire-resistant glass for portholes and fire-resistant glass for rectangular windows, the outer surface glass plate is tempered safety glass, and the material type of the inner surface glass plate can be selected arbitrarily.

C class)

A single piece of fire-resistant glass meeting only the fire integrity requirements. This type of glass has the characteristics of light transmission, fire prevention, smoke insulation and high strength. It is suitable for fireproof glass partition walls, fireproof windows, outdoor curtain walls, etc. without heat insulation requirements.

Precautions for fireproof glass

1. Before choosing fire-resistant glass, you must first understand the specific requirements for fire protection of fire-resistant components composed of fire-resistant glass, whether it is fire prevention, heat insulation or smoke insulation, and fire resistance limit requirements.

2. Monolithic and compound perfusion fire-resistant glass cannot be cut with a glass knife like ordinary flat glass, and must be processed to length, but composite (dry-process) fire-resistant glass can meet the requirements of cutting.

3. When choosing fire-resistant glass to form a fire-resistant component, in addition to considering the fire-resistant and durable performance of the glass, its supporting structure and various elements must also meet the needs of fire resistance