There are basically two methods for the manufacture of tempering, one is physical tempering, and the other is chemical tempering.

1. Physical Tempering

The physical method of tempering, to put it simply, is to temper the glass.

The principle of the physical method is that after the glass is heated at a suitable temperature and then cooled rapidly, the surface of the glass will shrink sharply, resulting in compressive stress, while the middle part of the glass will generate tensile stress because it is too late to shrink, thereby promoting the glass to obtain high strength.

The general process is as follows: ordinary glass is cut out according to the shape of the product, and then the glass is heated to about 700 degrees close to the softening point, and then uniformly and rapidly cooled immediately.

Generally, 6mm glass needs to be heated at 700 degrees for 4 minutes, and then cooled evenly for 2 and a half minutes. If it is relatively thick glass, such as the common 10mm glass, it needs to be heated at 700 degrees for 8-9 minutes, and then cooled for about 5 minutes. The thicker the glass, the longer the tempering process will take.

2. Chemical Tempering

The principle of chemical toughened glass is to change the molecular composition of the glass surface through ion diffusion.

At high temperature, the glass is immersed in high-temperature molten salt, and the alkali ions in the glass exchange with the alkali ions in the molten salt, resulting in a “squeeze” phenomenon, which promotes compressive stress on the surface molecules of the glass and increases the strength of the glass.

Through this method, the molecular density of the glass surface is increased, and the compressive stress on the glass surface is increased. Since the increase in strength is obtained by ion exchange, it is also called “ion exchange tempering method”.

3. What are the advantages of tempered glass?

Through the above introduction, we know that tempered glass enhances the compressive stress on the glass surface through physical or chemical methods, improves the physical and chemical indicators of ordinary glass, and makes it have greater wind resistance, high and low temperature resistance, impact resistance, and features such as bends.

In summary, tempered glass has the following two advantages:

1. Improve the strength of glass

The bending strength of tempered glass is 3-5 times that of ordinary glass; the impact strength is 5–10 times that of ordinary glass; the resistance to rapid temperature changes can withstand 150 degrees of temperature change; the resistance to rapid cooling and heat is higher than ordinary glass The glass is improved by 2–3 times.

2. More secure

Since tempered glass improves the above physical properties, it is less likely to break and improves the fragility of glass. Even if it is broken under severe impact, it is still a fine particle, which reduces the harm to people.

4. What is the difference between physical tempering and chemical tempering?

1. The processing temperature is different

Physical tempering is generally carried out at 600-700 degrees, and chemical tempering is carried out at 400-450 degrees.

2. Different tempering principles

Physical tempering is high-temperature quenching of glass, and chemical tempering is sodium ion exchange plus cooling.

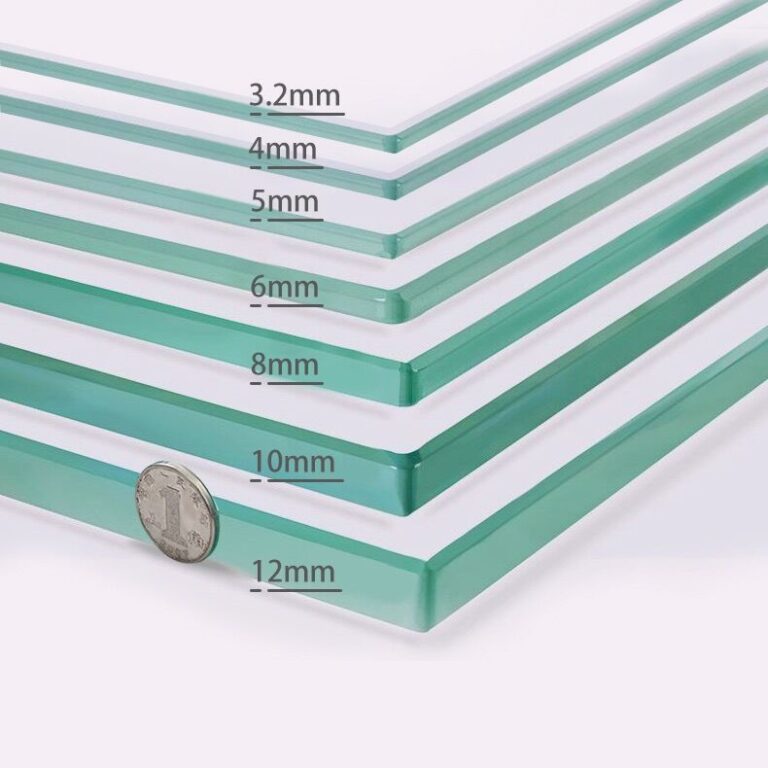

3. Different tempering thickness

Physical tempering can process 3.2–35mm ordinary glass, and chemical tempering can process 0.15–50mm glass.

4. The tempering stress is different

Physical tempering can produce a surface stress of 90Mpa–140Mpa, and chemical tempering can produce a surface stress of 450Mpa–650Mpa.

5. The broken state is different

Physically tempered glass is broken into particles, and chemically tempered glass is broken into small pieces.

6. Different impact strength

Physically tempered glass has the advantage of being greater than or equal to 6mm, and chemically tempered glass has the advantage of being less than 6mm.

7. Others

Bending strength, chemically tempered glass is better than physical tempered glass.

Optical performance, chemical tempered glass is better than physical tempered glass.

Surface flatness, chemical tempered glass is better than physical tempered glass.